Innovations in Motion

View All

Construction & Materials

Design

Maintenance

Safety & Traffic Operations

Driver & Vehicle Services

Multimodal

Planning & Research

Other

Over the roads, on the railways, in the air and on the water, PennDOT's transportation network is the crucial connection between Pennsylvanians and their livelihoods. Our crews, nearly 12,000 strong, are in our communities ensuring safe and efficient access to work, school, critical goods and services, and more. Maintaining such a vast network requires continual improvement to adapt to changing technology and implement best practices. To meet that goal, our team is always looking for ways to innovate.

In every corner of the Commonwealth, the PennDOT team is deploying smart and innovative approaches to doing business and delivering value and reliability.

Innovations at PennDOT are employee-driven, whether from innovation committees, the State Transportation Innovation Council (STIC), or the Federal Highway Administration's Every Day Counts Program. Our team continues to drive Pennsylvania forward by suggesting, developing, piloting and implementing these transportation innovations.

Among the innovations in this publication are upgrades to our technology to keep travelers and work crews safer, changes to processes that will move PennDOT fully into a digital future, and adjustments in procurement to help lower greenhouse gas emissions and promote green transportation. Here are just a few examples of what those efforts are yielding:

Many innovations are in their second or third year of development and deployment, while some are just getting off the ground. This publication represents only a portion of the efforts made every day by the dedicated public servants that make up the PennDOT team.

I couldn't be more excited to see PennDOT build on these updates and upgrades that I know will have a long-lasting impact on the lives of all Pennsylvanians.

Thank you for taking the time to explore this innovative work. And thank you to the team at PennDOT for everything they do to make these innovations happen for Pennsylvania travelers.

Michael Carroll

PennDOT Secretary

Miles of Roadway

Bridges

Transit Systems

Public-Use Airports

Ports

Operating Railroads

Licensed Drivers and ID Card Holders

Registered Vehicles

Engineering Districts

Total Employees

Maintenance Employees

Explore the top innovations that shaped the past year, from transformative technologies to impactful projects.

View All

Construction & Materials

Design

Maintenance

Safety & Traffic Operations

Driver & Vehicle Services

Multimodal

Planning & Research

Other

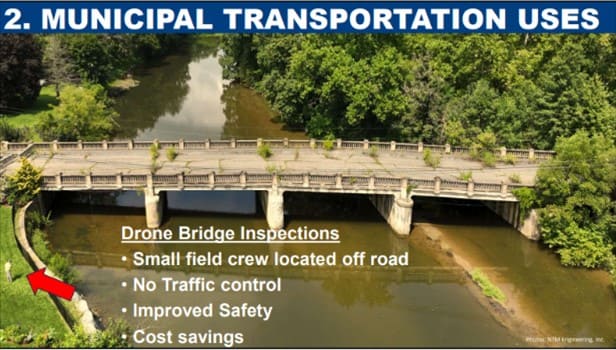

Bridge inspection crews in PennDOT's Engineering District 2, based in Clearfield, Pa., have found an innovative way to improve safety and efficiency while conducting inspections. Members of the district's Bridge Inspection Unit, Bridge and Structural Drafter Mark Swanson and Transportation Construction Inspector Zachery Kennedy, suggested the use of a GoPro camera to allow crews to get a better look at hard-to-reach places without setting up a ladder or scheduling a crane.

.jpg)

The GoPro, mounted on a 30-foot pole, offers Bluetooth connectivity to the bridge inspector's iPad. Viewing the tops of bridge abutments and piers using the GoPro can help determine if scheduling the bridge crane or setting up a ladder is even necessary. If initial review with the GoPro doesn't show issues, no further inspection is necessary. If something visual is noted, then a physical inspection with the bridge crane is scheduled or a ladder is utilized. Use of the GoPro can help save time and money and improve safety.

Typically, crews carry an 18-foot ladder to assist with viewing the tops of bridge abutments and piers from the ground. However, setting up ladders along bridge abutments and/or piers can be unsafe due to the nature of the underside of bridges, which often contain uneven ground, large rocks, and other potential hazards. While scheduling the use of a bridge inspection crane is another option, this requires traffic control setups and puts crew members adjacent to traffic.

"The main consideration for us was safety," said Swanson. "Placing a ladder in the middle of a creek, or on unstable ground under a bridge, or on the white line on Interstate 80 to inspect an overpass, can all be dangerous. With this method, we can see exactly what the camera is seeing on the iPad and determine if there is a need for a more thorough inspection without taking a lot of unnecessary risks. It also makes the work much faster and more efficient."

District 2 has 3,731 total road miles and 2,188 total bridges.

Read More Construction & Materials Stories

The State Transportation Innovation Council (STIC) facilitates the rapid implementation of proven, well-researched and documented state, regional, national and international transportation innovations that are new to Pennsylvania. The STIC also supports and promotes the implementation of Federal Highway Administration (FHWA) Every Day Counts (EDC) innovations.

During winter snow events, as trucks treat and plow Pennsylvania roadways, the tailgates can become coated with snow, slush, and dirt. This covers critical safety features, such as reflectors and lights. With lower visibility, trucks can often be involved in "hit from behind" crashes.

Nearly half of every reported "hit from behind" crash happens during a snow event. Poor visibility between the plow truck and the motorist is the main cause. The air foil attachment innovation helps to improve visibility with a goal of reducing these crashes.

The air foil attachment was piloted between 2015 and 2017 by the Oregon Department of Transportation (Oregon DOT). It is similar to a spoiler on a vehicle. Like a spoiler, the purpose is to change the flow of air on a vehicle. The air foil is mounted to the top of the truck tailgate and directs air onto the backside of the truck to keep the tailgate clear of debris.

The Armstrong County maintenance organization, based in PennDOT's Engineering District 10, learned about the air foil through a Clear Roads Convention, where representatives from states came together to share their best practices in maintenance. After talking with Oregon DOT, Highway Maintenance Manager Aaron Raible and Welder Corey Neal began to work on plans to include it in their winter operations. Raible also introduced the innovation through the State Transportation Innovation Council's Maintenance Technical Advisory Group with the hopes of expanding its use to other regions of the state.

"We saw the benefits of the air foil," said Raible. "Improving visibility and having employees spend less time cleaning the tailgates with more time on the roadways was worth going through the pilot. It also increases the lifespan of our equipment with less wear and tear on the tailgates."

The county created an air foil by repurposing outdated tailgate brine tank brackets and tested it during the 2023 and 2024 winter seasons. During testing, the county made changes to the air foil to make it lighter and safer. It was changed from steel to a plastic poly material, which reduced the weight by half and adjusted the angle of the mounting to better direct the air flow.

"The air foil is a great safety improvement to our trucks," said District 10 Executive, Brian Allen, P.E. "We look forward to doing some more testing in our other counties and increasing the use of it to improve safety and cost savings."

The next step will be to test the air foil on roadways with different traffic volumes and speed limits this winter.

Read More Maintenance Stories

When Eric Kinard took over as permits manager for PennDOT District 8, based in Harrisburg, Pa., he discovered consultants hired to review Highway Occupancy Permits (HOPs) for the district were spending up to eight hours a week fielding phone calls from applicants with questions about application review comments.

Spending the equivalent of a full workday away from what they needed to be doing - reviewing HOP application submittals - was not an efficient use of the reviewers' time, especially with the District 8 Permit Unit's enormous workload. In recent years, district HOP staff have been processing more than 5,000 application submittal reviews annually. It's one of the busiest HOP offices in the state.

The problem was reviewers were returning these submittals with the same comments repeatedly due to the initial comment not being addressed. It was clear applicants didn't understand the reviewer's comments.

Kinard's solution was to create specific hours each week where applicants could schedule time for collaboration meetings to discuss HOP applications and questions related to their submissions. Two hours were set aside each week, providing applicants with an opportunity to schedule 20-minute blocks to discuss applications with Kinard and HOP Manager William Warden.

"The applicant team can request a 20-minute time slot where they can ask us any question pertaining to their application," Kinard said. "If they don't understand a comment or it's confusing, we can help provide clarity."

The applicant is required to submit a meeting agenda that includes discussion topics and/or questions about specific review comments to allow district HOP staff an opportunity to perform research and pull together information prior to the meeting. Minutes from the meeting must be submitted by the applicant following the meeting, and those minutes must be attached to their resubmission.

The 20-minute time slot was chosen so each session would be brief and focused on the questions at hand. According to Kinard, it turns out that 20 minutes was the perfect number. Applicants cut to the chase and show the team exactly what they don't understand about the comments.

"We realized it was an opportunity to expedite the process - shorten the whole review process," Kinard said. "It freed our review team from getting bogged down with questions and provided efficiency by keeping them focused on their current workload."

According to Warden, District 8 has been hosting the meetings since April 2023. Since the program has been implemented, a Strike-Off Letter was issued establishing a process for HOP units in the other PennDOT districts to hold collaboration meetings.

"These meetings have cut back on the phone calls and emails that the Distrcit 8 HOP Unit has received to answer questions from our return comments," Warden said.

According to Warden, this allows the unit to be more productive and provide better customer service to the HOP applicant and their design teams to clarify return comments and discuss possible solutions that could bog down the HOP process for the property owner.

"The applicants just want decisions and clarity," Kinard said. "There are fewer repeat comments. It takes the guess work out of it."

Read More Design Stories

The State Transportation Innovation Council (STIC) facilitates the rapid implementation of proven, well-researched and documented state, regional, national and international transportation innovations that are new to Pennsylvania. The STIC also supports and promotes the implementation of Federal Highway Administration (FHWA) Every Day Counts (EDC) innovations.

PennDOT maintains more than 96,000 snow-lane miles statewide, which is enough to circle the globe nearly four times. To tackle this task, PennDOT uses approximately 2,200 department plow trucks, operated by roughly 4,700 on-the-road workers, braving the worst of winter to keep roadways passable and safe.

Over the last few years, employees in PennDOT Engineering District 11, based in the Pittsburgh region, and PennDOT Engineering District 10, based in Indiana, Pa., worked with the State Transportation Innovation Council's (STIC) Maintenance Technical Advisory Group to pilot adding cameras into their truck fleet.

Integrating forward-facing cameras in plow trucks with PennDOT's existing Automated Vehicle Locator system enhances real-time situational awareness of road conditions during winter weather events, rather than relying solely on interstate traffic cameras, which are primarily installed on interstates.

This innovation allows district maintenance management, incident command staff, area command staff, as well as Pennsylvania Emergency Management Agency staff the capability of better resource management and allocation and assisting in decisions regarding speed and lane restrictions. Beyond winter operations, the cameras are also being used for non-winter maintenance activities, such as line painting.

"We continue to see many benefits from use of these cameras," said Allegheny County Maintenance Manager Ben DeVore, P.E. "When you can't see the roads using the traffic cameras, we use the cameras on the trucks to give us a better view of roadway conditions."

Following a successful pilot deployment in Districts 10 and 11 during the 2022-23 winter season, which included cameras in 40 snowplows, three paint trucks, and 27 assistant highway maintenance manager vehicles, District 11 equipped its entire Allegheny County dump truck fleet with cameras and purchased cameras for its remaining dump truck fleet in Beaver and Lawrence counties, totaling 208 cameras. Additionally, as of spring 2024, PennDOT District 10 had 34 of its vehicles outfitted with cameras, and PennDOT Engineering District 2, based in Clearfield, Pa., installed the cameras for use with its line paining operations. PennDOT Engineering District 6, based in King of Prussia, Pa., is also installing the cameras on trucks in Philadelphia County.

Read More Maintenance Stories

Leveraging Federal Highway Administration (FHWA) Technology Transfer (T2) Program funding, PennDOT, along with the Maryland Department of Transportation (MDOT), co-hosted a multiday Research and Implementation Peer Exchange in August 2024.

The goal of the Peer Exchange was to discuss research topics, best practices and challenges related to communicating the value of research, research implementation and knowledge management. It included participants from the Mississippi DOT, Texas DOT (TxDOT) and Utah DOT (UDOT), as well as representatives from the FHWA Pennsylvania and Maryland Division offices and FHWA Headquarters.

"It was a lively discussion from many state subject matter experts," said Yathi Yatheepan, P.E., from FHWA's Pennsylvania Division Office. "The discussions provided an understanding of what is different and what are the common practices among the states."

Following each DOT providing an overview of their research programs, three key topic areas were discussed by participants - Communicating the Value of Research: Who to Tell, How and When; Research Implementation, Monitoring and Communication of Benefits; and Knowledge Management and Retention.

"The willingness of the participants to engage in dialogue during the peer exchange made the experience really enjoyable and valuable," said Brian Wall in PennDOT's Bureau of Planning and Research. "The interaction and networking among the participants were key to conducting a successful event."

Director of TxDOT's Research and Technology Implementation Division, Kevin Pete, led participants in sharing best practices and brainstorming improved approaches for communicating the value of research, which focused on the audience, communication methods and timing of messaging. One of the central themes of the discussion was the importance of determining and communicating both qualitative and quantitative measures of success.

Participants shared a variety of ways they communicate project successes to their agencies, the public, other state DOTs and other governmental agencies. Webinars, short video summary reports, social media, dashboards, research road shows, staff recognition, testimonials, posters, project spotlight emails and online publications, articles and libraries were all given as examples of effective communication methods the participating DOTs had explored.

"I learned to define 'value' at the level of the audience you want to reach and to craft your message accordingly," said Steve Wyatt, with the Maryland DOT.

Led by Director of Research and Innovation at UDOT, Cameron Kergaye, Ph.D., P.M.P., P.E., the discussion on research implementation and monitoring centered around the importance of thinking about implementation at the beginning of the process and ensuring everything that is done throughout the process lends itself to implementation.

During the session, participants shared and discussed similarities and differences of their respective programs along with best practices and strategies to overcome challenges. The group discussed the importance of having the right champion in place to utilize and implement the research. To ensure overall success of the project, Dr. Kergaye noted that the champion should be at the right level of the organization, have enough time available to dedicate to the research project and possess the necessary subject matter expertise.

During the session, Dr. Kergaye also stressed the importance of assessing projects, whether it is paying back benefits and which program areas in the organization are good at implementing research results. According to Dr. Kergaye, this allows an organization to obtain a complete picture and a better understanding of how research results are being implemented and derive the associated benefits from implementation.

State Research Engineer at the Mississippi DOT, Cynthia Smith, P.E., led participants in exploring the definition of Knowledge Management (KM), getting leadership buy-in and support for KM, embedding KM into an organization's culture, implementing effective KM strategies and tools and identifying organization-wide champions who can focus on and prioritize KM.

Participants acknowledged that getting a KM program established is essential in any organization and discussed tips for laying the foundation for a strong KM program, which included: defining KM for the agency; making KM an agency strategic focus; identifying knowledge gaps from the start; using multiple approaches to KM; conducting KM research studies; documenting anything and everything available; storing documentation electronically; ensuring easy access to organizational charts; and ensuring easy access to stored information.

Through discussions, participants concluded that it takes time and dedication to build a culture of KM in any organization and the importance of building relationships to assist with KM efforts, which includes: conducting field site visits, coordinating research roadshows, holding one-on-one meetings with organization leaders and identifying designated KM liaisons all help with these efforts.

"I learned that all DOTs presently struggle with this effort, and we are not alone," said Wyatt. "KM can have many forms and emphasis areas. Expertise management is an area we need to focus on to help with our succession planning efforts."

With each topical area, Peer Exchange participants discussed key takeaways and considerations, next steps and available resources to help make enhancements to their own programs.

"I really liked the discussion among the states and to really dig into the 'why' of what we do and figure ideas for future activities," said Pat McVeigh from PennDOT's Bureau of Planning and Research.

Read More Planning & Research Stories

The State Transportation Innovation Council (STIC) facilitates the rapid implementation of proven, well-researched and documented state, regional, national and international transportation innovations that are new to Pennsylvania. The STIC also supports and promotes the implementation of Federal Highway Administration (FHWA) Every Day Counts (EDC) innovations.

.jpg)

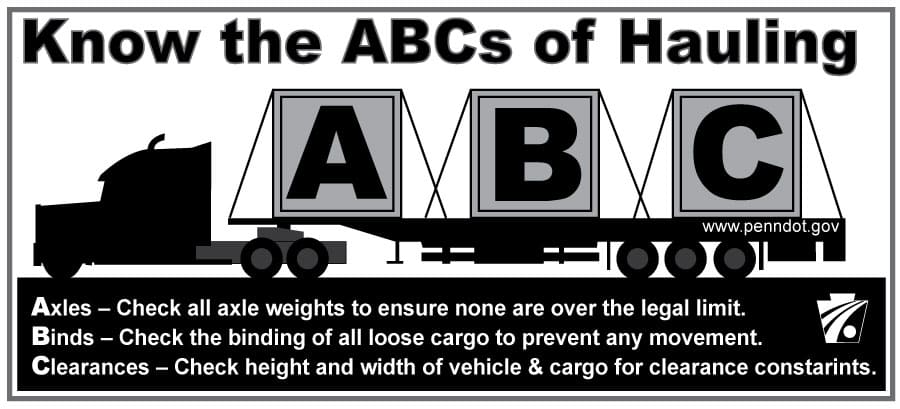

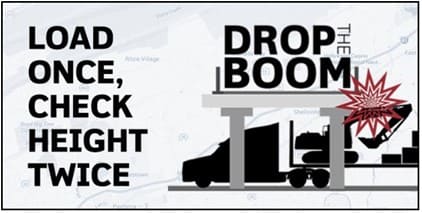

Vehicles striking bridges is an issue in Pennsylvania and throughout the country. These "bridge strikes" occur when a vehicle exceeding the clearance height of a bridge "attempts" to pass underneath it, resulting in a collision. While it's challenging to determine the exact number of bridge strikes, PennDOT crash records include 70 bridge strikes in 2023 alone. Bridge strikes can lead to serious damage to both the vehicle and the bridge itself, with public funding often needed to repair the damage.

Most bridges are designed with a minimum of 13 feet 6 inches (13'6") of clearance between the road and the bottom of the bridge. This height provides sufficient clearance for automobiles and commercial trucks to safely pass underneath. However, some older bridges are lower than 13'6" and include signage to warn approaching drivers of the lower height.

Strikes at low-clearance bridges have resulted from commercial trucks detouring from major highways, rental truck drivers unfamiliar with the height of their vehicle, and more. However, bridge strikes are not limited to low-clearance bridges. Some strikes are the result of oversized vehicles traveling on roads beyond their permit, while others are due to the height of equipment on trailers or truck beds not properly lowered before travel.

In recent years, PennDOT has added bridge information to the state's traveler information system (511PA), including locations of low-clearance bridges, weight posted bridges, and bridge closures. PennDOT has also developed two public information campaigns targeting commercial drivers hauling construction equipment and cargo.

A study is currently underway to better understand where bridge strikes occur, under what conditions, and by whom. This type of information, along with an understanding of best practices used in other states, can help identify ways to prevent them. PennDOT's ultimate strategy will include the following categories: regulatory, educational outreach, technology and partnerships, engineering, operations, and enforcement.

The educational outreach strategies will include working with rental companies to educate rental drivers who are often unaware of the height of the vehicle they are renting. This, in turn, means they are also unaware of the potential hazards of low-clearance bridges.

"It's in the rental company's best interest, as well as the state's, to educate renters on this topic, said Chief of PennDOT's Highway Safety and Traffic Operations Division Doug Tomlinson, P.E. "By working with Pennsylvania rental companies, PennDOT hopes to reduce the nearly 10% of bridge strikes that involve rented vehicles."

One of the engineering strategies will be the use of "sacrificial infrastructure." This infrastructure, deployed ahead of or on a bridge, will allow vehicles to strike the device instead of the bridge itself, resulting in a much lower cost repair.

A single strategy won't solve the bridge strike issue. It will require a multifaceted approach, a thorough understanding of the challenges, and a willingness to work creatively to reduce bridge strikes across Pennsylvania.

Read More Safety & Traffic Operations Stories

The State Transportation Innovation Council (STIC) facilitates the rapid implementation of proven, well-researched and documented state, regional, national and international transportation innovations that are new to Pennsylvania. The STIC also supports and promotes the implementation of Federal Highway Administration (FHWA) Every Day Counts (EDC) innovations.

In today's fast-paced and ever-evolving environment of digital transportation, many opportunities exist for enhancing current project delivery processes from design to construction. Whether it is part of the Federal Highway Administration (FHWA) Every Day Counts Round 3 (EDC-3) and EDC-4 e-Construction innovation, the EDC-6 e-Ticketing and Digital As-Builts innovation, or PennDOT's 3D2025 Digital Delivery Directive, PennDOT continues to champion the use of paperless technologies and is leading the way in the digital transformation of project delivery and e-Construction management.

The advancement of these innovations has resulted in improved accessibility of project data, enhanced safety, better quality, and time and cost savings. While PennDOT's digital transformation started well over a decade ago, the department has since blossomed from the initial starting point and continues to improve and expand current processes. Over the years, PennDOT has built several internal customized solutions that help PennDOT teams be more successful in their everyday jobs, while reducing the need for paper copies.

As the systems advance and evolve, one of PennDOT's main goals is to bridge opportunities and capitalize on system interoperability to help streamline project delivery processes, not only for PennDOT employees but also for external partners. PennDOT's Project Delivery Collaboration Center (PDCC) helps accomplish exactly that.

"The PDCC is designed as a hub for all our designers and project managers and connects all of PennDOT's various legacy systems," said Kelly Barber, P.E., chief of the Engineering Automation and Services Division in PennDOT's Bureau of Construction andMaterials. "It allows them to easily access all legacy solutions, pull in needed data and store project files."

The hub is currently available to PennDOT employees and will become available to PennDOT's external consultants in 2025. Accessibility to external partners will further streamline the project delivery process as the system allows users to track the workflow of design submittals in one central system, providing designers with the opportunity to see where their projects are in the approval process and increasing accountability. Diving further into the virtual world and PennDOT's e-Construction efforts, the department continues to explore the possibilities of Augmented Reality (AR) and Construction Analytics as well as the use of Unmanned Aerial Systems (UAS) and tying these efforts into the PDCC. The bi-directional interconnectivity with the PDCC ensures that the entire construction team is able to see what is going on with the project and can process and resolve issues quickly and effectively.

"We want to ensure that we have a digital backbone that is platform inclusive and allows the department as well as our business partners to capitalize on our investments," said Barber.

Use of AR in the field can expedite problem-solving as it allows for real-time collaboration by field and office personnel. It brings the design intent to the field for any conflicts or issues resolution and provides for all contract documents at the touch of a button.

To date, PennDOT has piloted various AR software packages, including Reconstruct, Datumate and Multivista, which also tie in UAS imagery to monitor construction progress and additional analytics, depending on the software.

The Reconstruct software can use drone captures to create 3D reality models, which allow the construction team to thoroughly document progress and provide the ability to navigate the construction site to see additional details and measure any part of the site with sub-inch accuracy.

PennDOT also piloted the usage of Imajion in PennDOT Engineering District 11, based in Bridgeville, Pa., for bridge inspection, construction, design, and materials testing. Imajion is the platform that connects the office to the field via a HoloLens to allow for a hands-free device and communication tool.

The Structural Materials Section in PennDOT's Bureau of Bridge, in coordination with High Steel, utilized AMA XpertEye, a smaller AR device, on PennDOT Engineering District 6's Betsy Ross Bridge Project in Philadelphia, for steel fabrication and documented the advantages of utilizing AR for remote visual inspection.

Moving forward, PennDOT will continue to evaluate the use of AR and UAS as possibilities evolve, and their adoption will likely play a key role in PennDOT's continued digital transformation.

Read More Construction & Materials Stories

.jpg)

After an incident on an interstate, there are two priorities. First, ensure the scene is safe for emergency responders. Second, clear the trapped traffic queue safely and as quickly as possible. Use of interstate crossovers are generally the fastest and easiest way to accomplish these goals. The challenge is that not everyone is as familiar with where the crossovers are located as are PennDOT equipment operators. The operators service these roads every day, know those crossover locations by heart, and even have developed nicknames for them. However, when incidents occur, those nicknames do not necessarily help first responders.

This is why employees from PennDOT's Engineering District 2 Centre-Clinton County maintenance organization developed a map that shows where every crossover lane on Interstate 80 and Interstate 99 is located. The map was shared with county maintenance organizations with interstate lane miles within their limits. It was also shared with PennDOT's Central Regional Traffic Management Center and Pennsylvania State Police.

"That way we're all speaking the same language," said Pete Kempf, senior highway maintenance manager for Centre and Clinton counties.

.jpg)

Kempf said the need for this tool was identified before the start of winter in 2023. Back then, two of his employees spent about a week using Google Maps to pinpoint where each crossover along District 2's interstate corridors were located. After that, they used Microsoft Word to create the highway crossover map.

The map also shows which crossovers are paved and which are gravel. Knowing whether the surface is paved or unpaved helps to inform decision making on whether or not the lane can support the weight of commercial vehicles or emergency response vehicles without getting stuck.

"These maps are a tremendous help for operations, especially when we stand up our incident command center during winter storms," said District 2 Traffic Operations and Intelligent Transportation Systems Manager James Roman. "They improve our situational awareness so we can quickly divert resources to drivers in need, relieve trapped queues and open roadways faster."

Read More Safety & Traffic Operations Stories

The team in PennDOT's Engineering District 6, based in King of Prussia, Pa., continues to look to the future and incorporate environmentally responsible and cost-saving work practices. The latest innovation is the Philadelphia County maintenance organization's new debris and dirt screener, which is expected to save PennDOT $1 million per year and help recycle material.

"Our team is consistently looking for new and innovative ways to streamline our transportation technologies in order to provide the best services to the public," said PennDOT District 6 Executive Din Abazi, P.E. "We are proud of our District 6 team that continues to offer creative ideas to help transform our work practices for today and tomorrow."

Crews use the debris and dirt screener by loading the materials collected on state highway shoulders by a sweeper truck into the top of the machine, where it is then sifted through a screen. The dirt is then automatically separated from debris. The machinery allows the county to properly dispose of collected materials and is expected to save the department in rental and disposal costs.

According to Philadelphia County Senior Highway Maintenance Manager Daniel Graham, through separating the dirt from such items as rocks, stones, or trash, the soil can then be reused by crews as clean fill at job sites or along highway shoulders.

In addition, Graham noted that the 20 feet by 8 feet by 12 feet new screener, located at a Philadelphia County stockpile, now allows PennDOT to clean the dirt without having to dispose of it in a landfill at higher costs.

"We now have the ability to screen the sweeper dirt and properly dispose of the trash within the dirt and then reuse or dispose of the clean fill at a much cheaper cost," said Graham. "We have also given the clean sweeper dirt to other counties to reuse as well."

The new equipment has also given crews a sense of pride through bringing the screening operation in-house instead of contracting out the service. Graham anticipates that the new equipment could provide other uses such as screening different sized aggregates. Overall, Graham sees the new equipment as a game changer.

"We can save costs through the ability to now screen, clean and reuse the dirt," he said.

Read More Maintenance Stories

In PennDOT Engineering District 4, based in Dunmore, Pa., the increasing number of priority items related to bridge maintenance had become a significant challenge. To address this issue, the Maintenance Task Force (MTF) was developed by Chief Executive for PennDOT's Highway Administration Deputate Jonathan Eboli, P.E.; Acting Assistant District 4 Executive for Maintenance Lonell Shalkowski, P.E.; Assistant Portfolio Engineer Jennifer Borino, P.E.; and Acting Maintenance Services Engineer Kaitlyn Drumheller, P.E.

The goal of the MTF is to reduce the number of priority items on its bridges and support the efforts of the district's Design Unit. Many bridges are located near bodies of water, which often requires obtaining permits from the Department of Environmental Protection (DEP), adding a layer of complexity to the maintenance process.

One of the key challenges in establishing the MTF was training newly hired Civil Engineer Trainees (CETs) to navigate the permitting process while they were simultaneously engaged in their first-year training. Additionally, the PennDOT employees responsible for carrying out the work must meet higher standards in efficiently completing this work, and a system needed to be developed and implemented to track the approval of permits and ensure completion before their expiration.

Despite these challenges, the MTF has proven to be highly effective. CETs are gaining valuable experience in the permitting process. They are also participating in team-driven projects that enhance their skills. This initiative has resulted in significant time and cost savings by reducing the reliance on external consultants for permit applications.

While it is challenging to quantify the exact savings, the efficiency gained through this in-house approach has streamlined bridge maintenance, making it both cost-effective and timely. The MTF has not only decreased the number of outstanding priority items but has also provided crucial learning experiences for CETs and fostered strong collaboration within the team.

"The purpose of the MTF was twofold," Borino said. "One was to give real-world experience to newly hired CETs and two was to help our district prepare permits for our many bridge priorities so that PennDOT employees could complete the maintenance work needed."

The success of the MTF demonstrates that with careful planning and teamwork, challenges can be transformed into opportunities. As a result, the MTF and its creators were recognized at PennDOT's annual Innovation Awards Ceremony in November 2024, as it serves as a prime example of innovation and efficiency in action.

"I am proud of the work our team has put into the MTF and look forward to their next innovative project to improve processes in the district," said PennDOT District 4 Executive Richard N. Roman, P.E.

Read More Maintenance Stories

The State Transportation Innovation Council (STIC) facilitates the rapid implementation of proven, well-researched and documented state, regional, national and international transportation innovations that are new to Pennsylvania. The STIC also supports and promotes the implementation of Federal Highway Administration (FHWA) Every Day Counts (EDC) innovations.

PennDOT is planning to pilot Cold Central Plant Recycling (CCPR) for roadways that experience heavy traffic. A State Transportation Innovation Council (STIC) innovation introduced by the STIC's Construction and Materials Technical Advisory Group (TAG), the transportation industry sees CCPR as a method for producing an asphalt base mix with lower greenhouse gas emissions and increased cost savings. Currently, PennDOT has specifications for CCPR use on roadways with less than 15,000 vehicles per day.

On average, asphalt mixes in Pennsylvania use 21% Reclaimed Asphalt Pavement (RAP), mixed at temperatures as high as 330 degrees Fahrenheit. CCPR, which has been used successfully on higher-volume roadways in Virginia, uses up to 100% RAP mixed cold with foamed asphalt binder or emulsified asphalt in a central plant. The central plant may be on-site or near the RAP supply. After the CCPR mix is produced, it is transported by truck to the project for placement using conventional paving and compaction equipment.

"CCPR is great for pavements that are in fair condition, where the pavement structure has moderate to severe distresses, but is not quite at the end of life, and the underlying materials are considered to still be in good condition," said Dr. Mary Robbins, P.E., director of Technical Services for the Pennsylvania Asphalt Pavement Association and CCPR innovation owner. "It is not meant to be a final wearing surface, so while it might be open to traffic during construction, it should be topped with an asphalt overlay or surface treatment."

CCPR provides an opportunity to utilize a valuable resource, RAP, which has been built up in some urban areas in the state. The only heat in the mix comes from the foamed asphalt binder, or emulsified asphalt, which results in low greenhouse gas emissions.

The CCPR Innovation Development Team is currently identifying and comparing PennDOT specifications with other state DOTs. Projects using CCPR in Virginia on Interstates 64 and 81 saw significant cost savings and sections of those interstates were completed in a much shorter timeframe.

"The use of this technology on higher-volume roadways will greatly expand the potential use of stockpiled RAP and the millings of ongoing projects," said Lydia Peddicord, P.E., chief of PennDOT's Pavement Design and Analysis Unit.

The CCPR innovation was awarded $93,000 in STIC Incentive Program funding in 2024 to develop a specification for higher-volume roadways. The STIC Incentive Program funding will be used for subject matter expert, Stephanie Drain, a national CCPR leader, to review and revise applicable specifications, mix design requirements and assist in project selection, as needed. The team plans to use Strategic Recycling Program funds for the required 20 percent state match for the STIC Incentive Program funding.

The CCPR Innovation Development Team is looking to pilot CCPR in PennDOT Engineering District 6, based in King of Prussia, Pa. The development team is currently working with the district to identify a project that will require the use of 30,000 to 40,000 tons of material.

Read More Construction & Materials Stories

The State Transportation Innovation Council (STIC) facilitates the rapid implementation of proven, well-researched and documented state, regional, national and international transportation innovations that are new to Pennsylvania. The STIC also supports and promotes the implementation of Federal Highway Administration (FHWA) Every Day Counts (EDC) innovations.

At PennDOT, the Traffic Systems and Management Operations (TSMO) Section in the Highway Safety and Traffic Operations Division is leading several unique data innovations.

The Lane Reservation (LaneRez) System, an innovation being championed by the State Transportation Innovation Council (STIC), will establish a process to "reserve" lanes for use in construction and maintenance road work. The LaneRez system will be a publicly accessible website, which will allow partners to add and update planned roadwork or special events. Information in the system will then be shared with Traffic Management Centers (TMCs) across the state through existing software systems as well as with third party mapping companies through a new Work Zone Data Exchange feed.

PennDOT's traffic offices will be able to review, plan and approve work directly through the LaneRez system. LaneRez will offer mobile device access for quick input and updates by field crews. Additionally, it will reduce phone calls from the field, highlight potential work zone conflicts, enhance smart work zone safety solutions to protect workers and motorists, and improve visibility and response to changing work zone conditions and incidents.

PennDOT continues to work closely with various stakeholders, including construction and maintenance crews, contractors, municipal organizations and planning organizations, to promote a successful implementation of LaneRez. LaneRez is anticipated to launch in summer 2025 after testing is conducted through the spring.

"We need to have a more complete understanding of where roadwork is taking capacity from all roads in order to better plan for the traffic impacts to our road users," said Chief of the Traffic Operations and TSMO Performance Section Ryan McNary. "LaneRez will provide users the tools needed to visualize anticipated traffic congestion and delays, conflict management of work being planned and performed, and a platform to activate or deactivate when workers are on scene to expand worker protection."

In addition to the LaneRez project, PennDOT has implemented a number of other strategies to mitigate recurring, unplanned and planned congestion. One notable strategy is the development of a Virtual Queue Protection system.

The project uses PennDOT's existing changeable message signs (CMS) to automatically alert travelers of slow or stopped traffic ahead. Slow or stopped traffic is detected by using real-time statewide traffic speed data, which comes from GPS data from vehicles on the road. When slow or stopped traffic occurs, messages are automatically displayed on signs approaching it. This gives travelers a chance to slow down before they get to the traffic.

"Unexpected queues on roadways with high speeds create dangerous conditions for motorists daily," McNary said. "We saw an opportunity to improve the safety around these events on our roads by designing a solution around an existing high-quality data subscription that provides PennDOT near real-time traffic speed data. The flexibility of this solution can be expanded to protect motorists and incidents on virtually all major interstates or highways in Pennsylvania."

PennDOT uses the solution in nearly 20 locations covering 600 miles of key roads in Pennsylvania. A study of the 11 locations that have been active the longest showed a 10% annual drop in all crashes, as well as a 13% drop in rear end crashes. These locations also showed a 35% drop in all fatal crashes and a 46% drop in fatal crashes involving commercial trucks. These numbers show that the system helped to prevent dangerous crashes where large commercial trucks crash into the back of stopped traffic at high speeds.

The drop in crashes also led to improved travel times on these roads. Vehicles traveling in these areas saw a total drop in travel times of nearly 76,000 hours per year. The travel time savings led to $2.3 million in cost benefits per year to travelers.

The project also led to cost savings for PennDOT. By using a virtual system that takes advantage of statewide speed data and existing signs, PennDOT avoided the cost of placing speed detectors and additional signs at these locations, which is needed for more traditional systems. The project has saved PennDOT over $7 million compared to using traditional systems.

As a result of these efforts, the National Operations Center of Excellence recently named PennDOT's innovative Virtual Queue Protection Corridor project the overall winner of their 2024 TSMO Awards.

With the success of the project, PennDOT intends to roll it out to more locations across the state and is studying areas where it might be most useful. PennDOT is also working to increase the number of portable CMS that can be brought into the system. This makes it easier to provide protection for temporary situations, like work zones. Bringing this innovation to more roads will only serve to improve safety for more Pennsylvania travelers.

In 2023, the Federal Highway Administration's STIC Incentive Program funding was awarded to further advance this project. PennDOT used the funding to purchase more than 150 4G modems, which contractors and PennDOT maintenance staff can "lease" from department traffic units. Once a CMS is connected, TMCs can better monitor work zone conditions based on traffic control plans. In addition, the network connection allows the CMS to be added to PennDOT's traffic management software where real-time traffic speeds, weather conditions and automated queue detection messages can be displayed. Future expansion may include long-term projects on the interstate or areas with frequent congestion-related incidents.

PennDOT is also innovating data usage to optimize the performance of traffic signals and reduce traffic congestion. Poorly-timed traffic signals are a significant contributor to traffic congestion on arterial roadways. Automated Traffic Signal Performance Measures (ATSPMs), an FHWA Every Day Counts Round 4 innovation, use macro, or "big," data to analyze and optimize the performance of traffic signals. ATSPMs can significantly reduce the need for expensive manual data collection to quickly deploy improved traffic signal timing.

The ATSPMs Pilot Program will use Miovision Traffop, a software platform that gathers signal operations data from 110 traffic signal intersections from across Pennsylvania. The platform then compares the information and condenses the data to a scalable report, which allows PennDOT employees and other traffic signal stakeholders to analyze the data to see what changes can be made to optimize traffic signal efficiency. PennDOT hopes to expand the use of ATSPMs throughout the state if the pilot program is successful.

"We are excited to begin this pilot program to measure traffic signal performance and take action to improve that performance," said Chief of the Transportation Systems Management and Operations Arterials and Planning Section Steve Gault, P.E., PTOE. "Most Pennsylvanians encounter multiple traffic signals each day, and this software will help all of us get more green lights."

Read More Safety & Traffic Operations Stories

Research plays a vital role at PennDOT and serves as an incubator for generating innovative solutions to provide the best and most efficient ways to deliver the highest quality transportation services.

The Research Program Management (RPM) Section, located in the Research Division of PennDOT's Bureau of Planning and Research (BPR), develops, manages and administers the PennDOT Research Program. The program strives to support the strategic agenda of PennDOT by initiating and managing project activities that seek to solve real-world transportation issues.

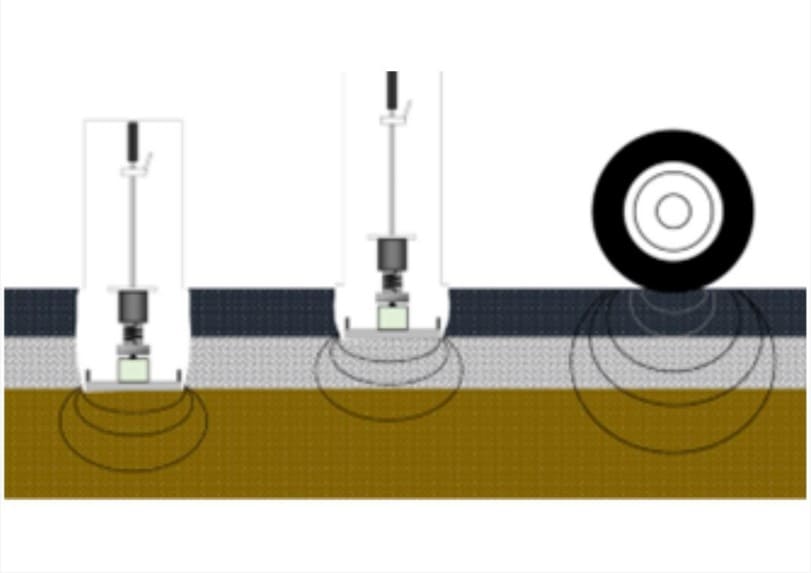

Through close coordination with project managers, technical advisors and research institutions, PennDOT completed several research projects in 2024, including the habitat credit program for pollinators/monarchs, bridge deck non-destructive evaluation testing, equipment and lift thickness optimization for structure backfill compaction operations, and lightweight deflectometer best practices. These projects provided the opportunity for PennDOT and world class experts to come together and explore new ways to address challenges and keep Pennsylvania on the cutting edge of transportation innovations.

To learn more about each research project, please select the name of the project below. For more information on these and other PennDOT research projects, please visit the PennDOT Research Projects page on PennDOT's website.

Read More Planning & Research Stories

The Self-Contained Skin Patching Truck is a single, truck-mounted unit that does the work of five tandem-axle dump trucks, a chipper spreader, and two oil distributors.

The truck is a highly mobile, computer-controlled unit, operated from the cab by one person. The unit can target and seal distressed roadway areas, preserve roads in a cost-effective manner, quickly move through the road network and prevent the formation of potholes. For example, being able to drive the unit from location to location without it needing to be transported by a larger truck greatly increased production and decreased staff hours.

"Berks County Manager Rick Stone and I discovered this unit that makes skin patching operations more efficient," Assistant District Executive for Maintenance Bruce Bubser said. "We received the go-ahead to pilot the truck, and so far, we are very satisfied with it."

PennDOT Engineering District 5, based in Allentown, Pa., rented the unit for 10 days at a cost of $38,625, which included the cost of an operator provided by the rental company. District 5 only needed to provide the safety set up and the rubber tire roller due to current specifications.

A typical skin patch operation has between 13 and 15 workers, a chipper spreader, and multiple dump trucks, so the Self-Contained Skin Patching Truck significantly reduces the number of workers and pieces of equipment necessary to patch a road.

The district plans to monitor the patched areas repaired by the truck for longevity and if the results are positive may expand its use.

"Bruce and Rick are outstanding employees dedicated to providing the best transportation system possible," PennDOT District 5 Executive Christopher Kufro said. "The innovation they are piloting will help to increase efficiency, while reducing the cost of maintaining our roadway network."

Read More Maintenance Stories

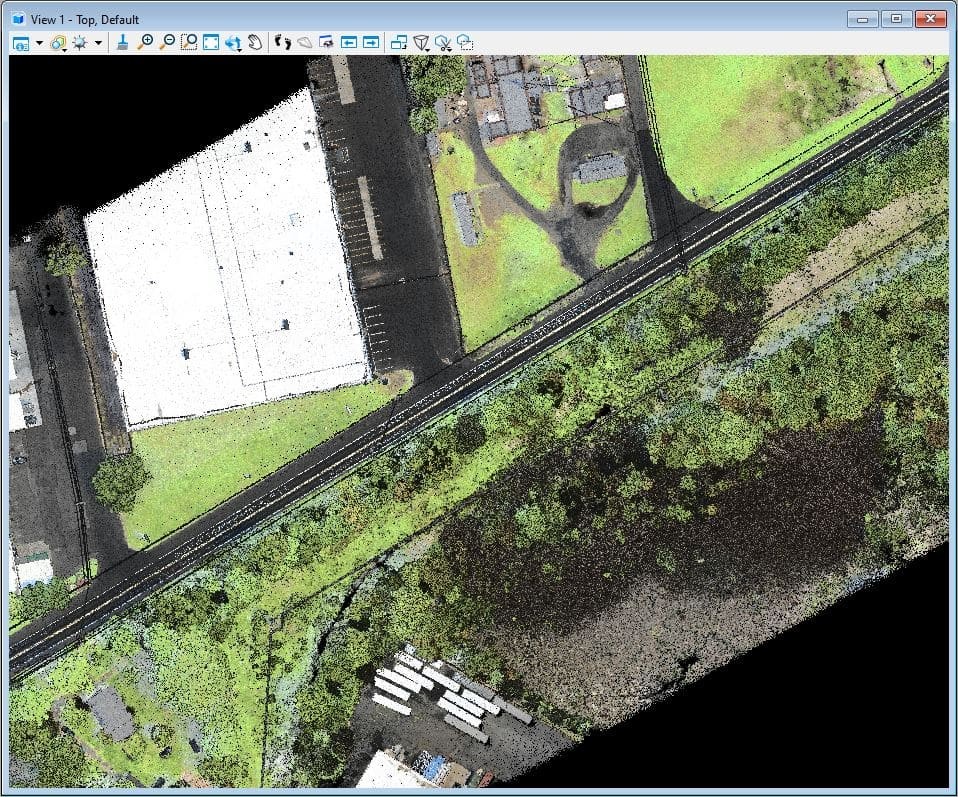

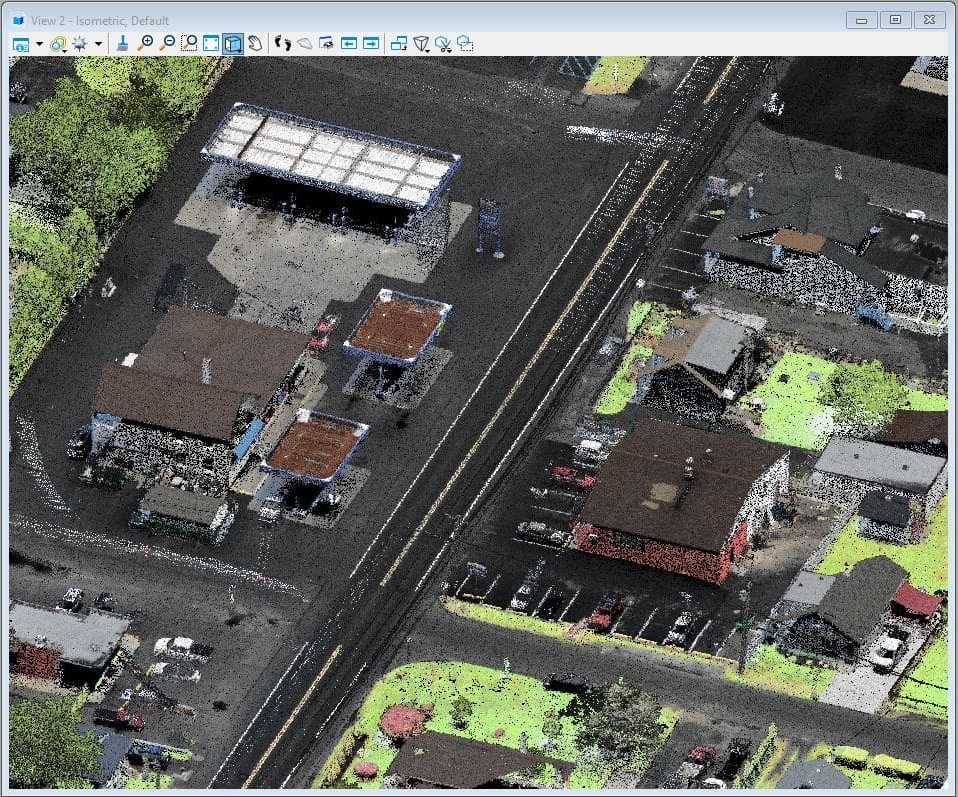

PennDOT's Photogrammetry and Surveys Section in the Bureau of Construction and Materials has been testing and using Unmanned Aerial Vehicle (UAV) Light Detection and Ranging (LiDAR) as another tool to improve geospatial data collection. UAV-based LiDAR has found a place in the gamut of services and technologies that have improved the way PennDOT collects existing ground surveys for highway improvement projects.

PennDOT partnered with T3 Global Strategies on three projects utilizing UAV-based LiDAR. The most significant was SR 2002-BE1. The project on State Road, located in Bristol Township, Bucks County, was for drainage, roadway, and signalization improvements. The project required sub-inch accuracy on the pavement and also required data 200 feet on either side of the corridor.

"For PennDOT projects flown with UAV LiDAR, we chose that tool because of the ability to achieve .06-foot relative vertical accuracy and a point density over 200 Points Per Square Meter (PPSM)," said Amy Lewis from T3 Global Strategies. The project became the subject of a two-part promotional video produced by the LiDAR manufacturer, GeoCue.

Modern remote sensing offers LiDAR and photogrammetry from many different platforms, and each platform offers advantages and disadvantages. The unique challenges of this project were best served with a combination of UAV-based LiDAR and photogrammetry.

While UAV-based photogrammetry is a great tool for small, non-vegetated areas and can be deployed very easily and affordably, it does have some disadvantages as well. It is difficult to achieve high accuracy over larger areas. Manual post-processing is also necessary for accurate feature identification and bare-earth extraction.

Adding LiDAR to the equation improves foliage penetration and adds accuracy and repeatability over larger areas. Adding intense post-processing to create Computer-Aided Drafting and Design (CADD) deliverables is also essential. For this project, stereograms were created from the LiDAR and photogrammetry. Those stereograms combine the vertical accuracy of the LiDAR with the horizontal accuracy and feature identification properties of the photogrammetry.

Results from the first three projects were encouraging. Robust testing confirmed that the Root Mean Square Error for State Road was 0.076 feet. This is an absolute number, as related to the true datum. Relative accuracies, or point-to-point accuracies within the data are better than the expected 0.06 feet. This was similar to the other two test projects. While more accurate technologies exist, the rapid mobilization and efficiencies of the UAV-based LiDAR process make it a great choice for small-to-medium-sized projects.

While the UAV program at PennDOT has grown quickly to more than 30 aircraft across the Commonwealth of Pennsylvania, PennDOT's in-house UAV LiDAR is just beginning. PennDOT currently owns one unit. After the success experienced with the first three projects, PennDOT may see more in-house units deployed on projects like State Road in the future.

Read More Construction & Materials Stories

The State Transportation Innovation Council (STIC) facilitates the rapid implementation of proven, well-researched and documented state, regional, national and international transportation innovations that are new to Pennsylvania. The STIC also supports and promotes the implementation of Federal Highway Administration (FHWA) Every Day Counts (EDC) innovations.

Every year, single vehicle, run-off-the-road crashes account for a large percentage of motor vehicle crashes. Some of these crashes take place along sharp curves, which typically contain chevron signs designed to warn and safely guide motorists through the area. The static, black and yellow signs are a beneficial safety tool, but some motorists might notice a new, brighter upgrade along roadways to help guide their way.

A Sequential Dynamic Lighting Curve Warning System, also known as lighted chevrons, is a system of sequentially flashing chevron signs that can help guide motorists through curves. The innovation, championed by the State Transportation Innovation Council (STIC), consists of lighted chevron-shaped signs to warn drivers of upcoming curves. The signs flash to guide the driver and help them navigate the roadway safety.

The benefits of these warning systems are even greater when visibility is lower. The flashing lights stand out to drivers during foggy, rainy, or snowy weather. They are also beneficial to driver's traveling at night or through work zones. The network behind the LED-enhanced solar or electric powered signs continuously communicates and provides a synchronization pulse to ensure the signs flash in proper order.

The Sequential Dynamic Lighting Curve Warning System has been piloted in nine locations in Pennsylvania - PennDOT Engineering District 1, based in Oil City, District 2, based in Clearfield, District 10, based in Indiana, and District 11, based in Bridgeville. Each of these pilots implemented the Sequential Dynamic Lighting Curve Warning System in different ways. The pilots have explored different types of locations, different power sources, and various types of materials for these systems.

One key area explored by these pilots was using hard-wired and solar-powered methods of providing electricity. Hard-wired systems may not always be possible if there is not existing highway lighting to utilize.

Districts 2, 10, and 11 chose to power their systems with solar panels. Solar-powered systems are easier to install and were generally less expensive. While solar panel installations can be impacted by shade or clouds, these pilots showed the impact on their performance to be minimal.

By evaluating speed and safety data that show a higher number of lane departure and truck rollover crashes, District 2 identified three locations to pilot the Sequential Dynamic Lighting Curve Warning System: I-99 in Centre County, Route 322 in Centre County and Route 22 in Mifflin County. The areas already had multiple countermeasures, such as static chevrons, curve warning treatments and pavement markings on the road, but the problems persisted in these locations. District 2 Highway Safety Unit Manager Ryan Collins and his team hoped to test the Sequential Dynamic Lighting Curve Warning System at these locations to see whether it could have an impact.

Collins said that he and his team received immediate positive feedback from the public once the system was implemented in these locations.

"Folks that live around [Centre County], and now in Mifflin County, believe [these devices] are truly making a difference," he said.

Collins and his team will gather and study data from these three locations, including a 5-year analysis to gather more extensive data. He hopes that future safety countermeasures will help end all crashes.

"I'm passionate about safety," he said. "I'm all for what we can do to engineer things and make things safer for motorists. [PennDOT is] taking strides in improving highway safety. Pennsylvania's goal is zero fatalities, and that is my goal. That is our goal."

The Sequential Dynamic Lighting Curve Warning System does require more planned maintenance than static signs. This additional maintenance is needed to ensure the lights continue to operate in the correct order. It also allows for time to adjust things like brightness to better suit the needs of drivers.

"When these systems have been knocked out a couple times, if you don't have replacements ready to go, repairs can take a while," said District 1 Senior Civil Engineer Supervisor Greg Maser.

This innovation expands the options available to address problem areas on Pennsylvania roads. These systems may be particularly useful in rural environments where crashes are more random, and low-cost solutions are needed.

"These systems add one more level in the toolbox to help PennDOT address the unique issues you may find on roads," said District 10 Senior Civil Engineer Supervisor Adam Marshall, P.E.

Each year, Pennsylvania performs numerous engineering improvements to reduce crashes and enhance safety on its roadways. While the longer-term safety impacts of the Sequential Dynamic Lighting Curve Warning System are still being analyzed, this innovation will continue to be a vital tool in the toolbox PennDOT uses to improve roadway safety. The versatility and low-cost of these systems can have significant impacts for drivers. Future efforts will expand on what has already been learned and inform further installations.

Visit www.PennDOT.pa.gov/Safety for more information on safety infrastructure improvement programs and safety countermeasures PennDOT implements throughout the state.

Read More Safety & Traffic Operations Stories

The State Transportation Innovation Council (STIC) facilitates the rapid implementation of proven, well-researched and documented state, regional, national and international transportation innovations that are new to Pennsylvania. The STIC also supports and promotes the implementation of Federal Highway Administration (FHWA) Every Day Counts (EDC) innovations.

How far can $125,000 go to advancing innovation in Pennsylvania? Since 2014, Pennsylvania has continued its effective use of FHWA STIC Incentive Program funding to advance a number of transportation innovation projects.

Innovative tools and techniques are proven to help reduce congestion, accelerate construction, enhance sustainability, and ultimately save lives. STIC Incentive Program funding is one of many tools that help provide resources to promote a culture of innovation across Pennsylvania. Rapid innovation development and deployment of these innovations is also a key factor to the success of the STIC. This funding can support and offset costs and push innovations across the finish line.

In Pennsylvania, STIC Incentive Program funding has been used to develop training programs, update innovation specifications, create strategic plans and facilitate business plans, pilot and upgrade technology, develop design procedures and tools, and host innovation-sharing events.

To learn about recent STIC Incentive Program projects, select the name of the project below.

Read More Stories In This Category

PennDOT Engineering District 11, based in the Pittsburgh region, had an ongoing issue with local wildlife impacting drainage on a few roadways in Lawrence County. Beavers were routinely building dams at the end of outlet pipes on multiple, four-digit state routes. Each time employees would notice standing water, they would schedule time to go out into small bodies of water in waders and remove the dams to help reestablish proper drainage flow.

County staff tried several techniques to prevent the beavers from building their dams; however, these techniques all failed, and the beavers were still able to block the pipes. Lawrence County Assistant Highway Maintenance Manager Scott Jones set out to find a way to prevent the beavers from causing more damage but in a cost-effective manner. Scott found that beavers are a big problem in Canada and after further investigation, found that they have had success using beaver cages.

In spring 2024, Jones met with Lawrence County Welder Jeff McKinney to discuss the cage and potential designs. The two began drafting ideas and were able to develop an agreeable design. After a few months of fabrication trials, McKinney was able to finish the first cage prototype.

Jones and McKinney sent the cage off for powder coating at a local ceramic coating shop in New Castle, Pa., to ensure extended durability in the water.

Since county crews installed the cage in June 2024, there have been no issues with roadway flooding or potholes from standing water, and the beavers have relocated elsewhere.

"For a cost of approximately $500, we are pleased with the results of this innovative approach to a unique situation and will be looking to utilize this on another roadway within the district," said Lawrence County Maintenance Manager Michael Horrell.

Read More Maintenance Stories

In the 1860s, public transit riders queued to buy tickets for seats on horsedrawn trolleys. Now, riders can track live bus locations and purchase trips with a few, simple smartphone taps. While transit agencies adopt various innovative technologies to modernize and improve services from administrative record-keeping to onboard entertainment, safety has always been a universal requirement. The challenge now for transit staff is learning how to protect these complex IT networks that simplify daily tasks.

Interruptions from attacks can have severe consequences with high costs from ransoms, restoration, and recovery. Transit agencies are increasingly common targets of cyber-attacks due to the broad disruptions these attacks can create in the communities they serve. Even after costs have been settled on a highly publicized attack, the damages to public trust may not be as quickly restored.

Joe Roselle, director of Administrative Services at Luzerne County Transportation Authority, recognized the need to "continue learning and evolving within the ever-changing landscape of cybersecurity."

However, due to the rapidly evolving technical landscape, safety and security is far more complex than time-delayed cash safes and routine oil changes. In the sea of resources published daily about cutting-edge cybercrime and corresponding protections, when would agencies find time to become experts at spotting phishing versus piracy? How would they start? Where would they look?

Seeing an opportunity to provide support for its transit agency partners, PennDOT's Bureau of Public Transportation (BPT) took the initiative to start the Cybersecurity Task Force (CTF) - comprised of representatives from BPT and transit agencies across the Commonwealth of Pennsylvania dedicated to providing focused assistance and awareness. The CTF focuses on the most common types of cyberattacks that transit agencies are likely to encounter. By increasing visibility of key vulnerabilities, agencies can better defend against attacks. The CTF also sifts through documents and publications to curate a set of resources that are most relevant to the specific needs of transit agencies across Pennsylvania.

"The task force has proved to be an invaluable resource available to all agencies, but especially valuable to the smaller ones that may be expertise and resource constrained," said Mike Slater, interim director of Information Technology at Centre Area Transportation Authority. "By distilling the mass of technical information to digestible formats, the CTF has saved agencies countless hours of potentially duplicative research."

In 2022, the State Association for Transportation Insurance required that all agencies in the coverage pool have an Incident Response Plan (IRP) for cyber liability insurance coverage. At the time, many agencies did not have an IRP. Consequently, the CTF focused its first webinar on IRPs and created a template IRP for agencies to use as a starting point. To further improve adoption and quality of IRPs for all agencies, the CTF is working with a vendor to conduct workshops across Pennsylvania, which will feature hands-on tabletop exercises to ensure agencies are periodically assessing and updating their IRPs.

To gauge the agencies' cybersecurity posture, the CTF asked them to complete a self-assessment. In retrospect, the process was too technical and subjective to produce reliable results. In the future, the CTF plans to use qualified vendors to conduct agency assessments. Additionally, some agencies are not in a position to take meaningful actions to improve their cybersecurity posture without additional regulations or compliance requirements to justify the time and investment.

To educate transit agency staff, the CTF produces quarterly webinars for Pennsylvania's transit agencies on important topics in cybersecurity. To date, the CTF has hosted eight webinars on topics including Multifactor Authentication, Phishing, Ransomware and Cybersecurity Supply Chain Risk Management. Additionally, the CTF disseminates cybersecurity information at Pennsylvania Public Transportation Association conferences and maintains a clearinghouse for references with a growing list of qualified, recommended vendors.

South Central Transit Authority IT Director David Avery explained that security has been included in nearly every standard audit and procedure.

"The CTF has provided good information over the years," he said. "The committee team and members provide a board to sound against and to learn new topics."

The CTF continues to meet twice a month, developing more support materials and references for transit agencies as they navigate the ever-evolving cybersecurity landscape. The CTF is planning their next webinar on cybersecurity considerations for legacy hardware and software in early 2025. Additionally, the CTF has recently kicked off an effort to develop a Pennsylvania Public Transportation Community Profile for the National Institute of Standards and Technology Cybersecurity Framework.

"Security is everyone's job," said Slater. "The task force makes that job easier."

The safety of its employees and contractors in roadway work zones is PennDOT's number one priority.

As drivers approach a work zone, there are several distractions to prevent them from seeing workers. It could be signs or work being done, drivers using cell phones, or even the movement of vehicles and machinery.

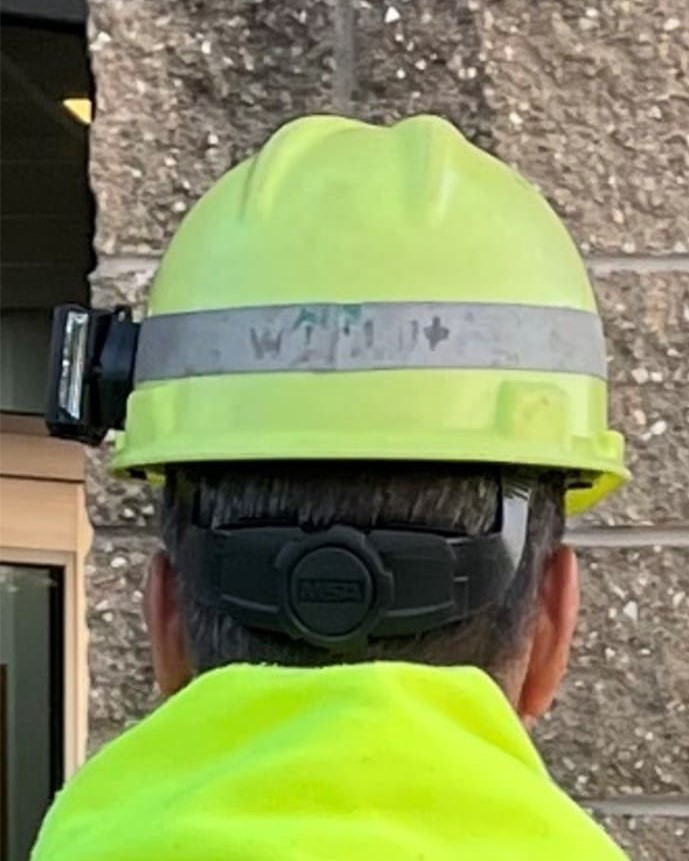

Employees in PennDOT's Engineering District 9, based in Hollidaysburg, Pa., are exploring how wearable LED lights can make workers more visible and reduce work zone accidents.

In September 2024, Cambria and Blair counties in District 9 launched a safety pilot using wearable white and amber lights, made by a company called Guardian Angel. District employees who worked on the project included: Advanced Safety Certificate Safety Specialist 2 Pam Kane; Transportation Equipment Operator B Matthew Foust; Assistant District Executive for Maintenance Dave Kammerer; Senior Highway Maintenance Managers Jacob Decker and Michael Peachy; and Highway Foremen Kirby Tucker, Walter Hughes, Brandon Chamberlain, and Matt Sunderland.

Wearable LED lights flash an eye-catching bright light and increase visibility in all conditions. The brightness of the LED lights is up to 800 lumens each, nearly as bright as police and emergency vehicle lights. The lights can be used during daylight or nighttime operations and worn on a reflective vest, T-shirt, or hardhat.

The pilot called for the lights to be first used by night crews performing crack sealing, bridge sweeping and bridge seam cleaning. Crews had previously placed triangular lights on stop/slow paddle signs to draw additional attention to the flaggers. Since the triangular lights could no longer be purchased, flaggers began wearing the lights on their equipment.

Wherever the lights are placed, they provide 360-degree range of light, increased visibility up to five miles away, and improved safety for the worker. The lights are more effective than reflective vests or tape, which are only visible from about 250 feet away, and only if light shines on them. The Transportation Research Board, headquartered in Washington, D.C., suggests that a combination of reflective clothing and wearable LED lights can reduce accidents at nighttime and in low visibility by up to 50 percent.

"The lights make the flaggers and anybody working around traffic feel safer due to increased visibility, and they ask for the lights now that they have used them," Foust said. "I hope the lights are put to use in every county and used as often as possible to reduce the number of injured workers and fatalities."

The cost of wearable LED lights ranges by size. The larger Elite Series is $120 per unit, while the Micro Series are $50 each. District 9 purchased the lights during a special offer, which provided a free Micro Series unit with the purchase of an Elite Series unit. Discounts are also available based on order size. Both types are rechargeable, eliminating the cost of batteries.

The next step for the safety pilot is to use the lights on stop/slow paddle signs throughout District 9.

Read More Maintenance Stories

Bruce & Merrilees Electric Company was the contractor on a $1.2 million safety improvement project along parts of Route 219/255 in Clearfield County last year. It consisted of upgrades to 11 traffic signals to help reduce traffic congestion and enhance safety through the corridor.

The corridor runs through the City of DuBois and Sandy Township. It serves as an incident management route for Interstate 80, which runs parallel to it between mile markers 97 and 101. The average daily traffic through this corridor ranges between 16,000 and 20,000 vehicles.

The contractor installed state-of-the-art signal controllers through the corridor. They directly connect with the Central Regional Traffic Management Center (RTMC), one of four RTMCs located across the state. This allows RTMC operators to activate preapproved detour timings to enhance traffic flow and ease congestion.

"We can't build our way out of congestion on this corridor," said District 2 Traffic Operations and Intelligent Transportation Systems (ITS) Manager James Roman. "There are railroad tracks on one side of the road and several businesses and land developments on the other side. We needed to identify operational solutions that made use of existing roadway capacity to keep traffic moving during routine and non-routine congestion."

The contractor also installed three "Type A" changeable message signs. Two sit along Route 219 near the ramps at Exit 97. One faces northbound traffic, and the other faces southbound. The third sits along Route 255 near the ramps at Exit 101. Since monochrome boards would be less effective at displaying symbols, all the signs are full-color, relay information on crashes or weather, and display messages with symbols to keep the traveling public informed.

Two closed-circuit televisions were also installed - one is located at the intersection of DuBois Street and Route 219, and the other is located at Park Avenue and Route 219. RTMC operators use the cameras to verify crashes, monitor roadway conditions, and decide whether the preapproved timings are working as intended. If not, adjustments can be made. The camera at DuBois Street was mounted to an existing, city-owned signal pole as a cost-saving measure. PennDOT entered an ITS Agreement with the city to realize these savings.

Radar was installed instead of traditional in-pavement loop detection. Radar collects enhanced high-resolution Automated Traffic Signal Performance Measures (ATSPMs) data. Analyzing it allows the RTMC to work with the city and township to decide on the best way to adjust the signal timings. The data also helps detect if drivers are running red lights at any of the signals. PennDOT shares this information with local police, and they decide on the appropriate steps. One option is a high-visibility enforcement wave.

"While the traffic signals are still owned and maintained by the municipalities, PennDOT is committed to improving operations through critical corridors," said District 2 Traffic Signal Supervisor Jonathan Tate. "By having this advanced technology, PennDOT now has data to see where and when improvements are needed and can implement adjustments right from the RTMC."

Read More Safety & Traffic Operations Stories

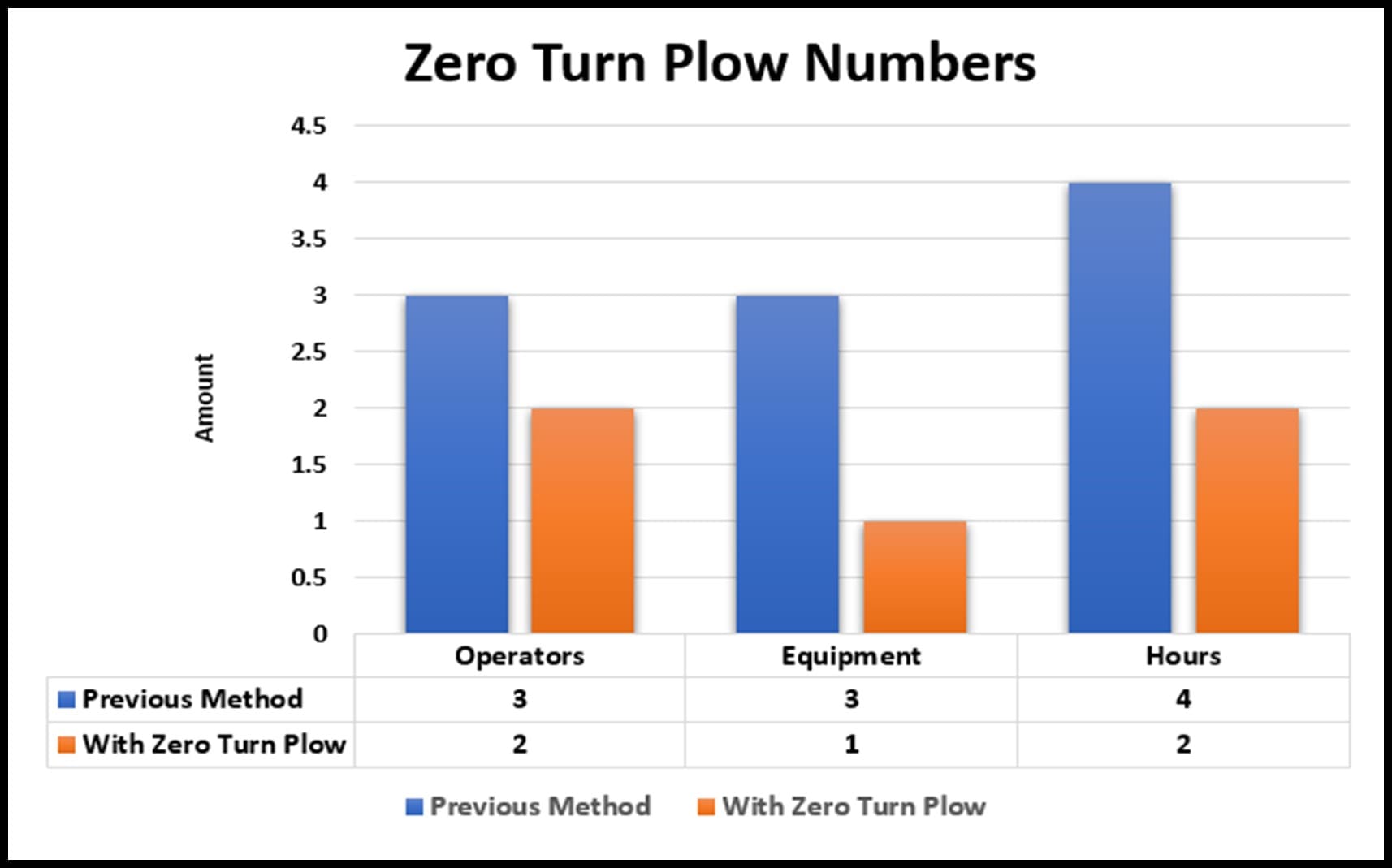

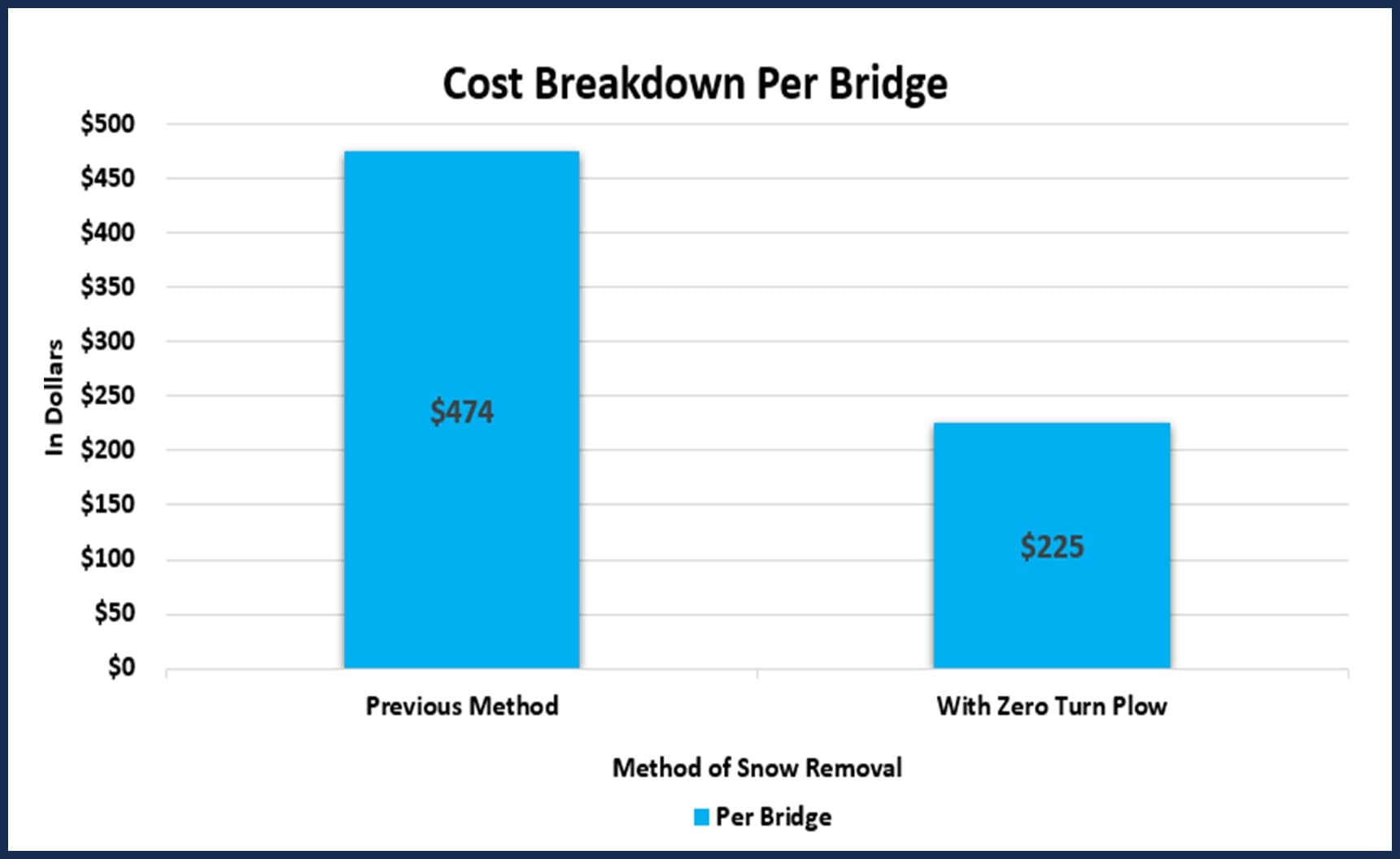

PennDOT is responsible for winter maintenance and snow removal in many areas, one of them being sidewalks on state-owned bridges. Northumberland County, in PennDOT's Engineering District 3, is responsible for maintaining the sidewalks of eight state-owned bridges for a total of 10,556 feet. Winter maintenance of the river bridge sidewalks can be a challenging responsibility for county maintenance forces, who also need to keep our roadways safe and passable in the winter.

These bridges serve a critical role to the motoring public and pedestrians by connecting communities and businesses all year long. To improve the safety and process of sidewalk snow removal, Northumberland County piloted the Zero Turn Plow to assist with these tasks.

The Zero Turn Plow eliminates the need for snow throwers, snow shovels and ice scrapers, allowing operators to clear snow from bridge sidewalks two and a half times faster than traditional methods and reduces the chances for injury.

Transported by two operators using a crew cab and trailer, the Zero Turn Plow can scrape off hard-packed snow caused by foot traffic. This reduces the need for deicing agents as well as decreases the potential for slip, strain, and sprain injuries to county employees that typically are the result of manually removing snow and ice from the bridge sidewalks.

Since the Zero Turn Plow has been incorporated, PennDOT's Northumberland County maintenance organization has seen a reduction in the average time it takes to clear a bridge sidewalk from 15 person-hours to six person-hours. This time savings results in a personnel cost savings of just over $2,100 per event. Due to these time savings, operators are able to shift their focus to other winter maintenance operations.

The overall review of the Zero Turn Plow has been positive in Northumberland County by improving the safety and efficiency of the crew members, which in turn increases the level of service to our customers.

However, while the Zero Turn Plow has worked well in Northumberland County, it may not be the best choice for every situation. Prior to investing in a Zero Turn Plow, managers should ensure that the measurements of the equipment work for the various locations in which you wish to use it.

The Zero Turn Plow has an adjustable width between 32 inches and 46 inches by means of bolt on plow extensions, which work for the sidewalks along the state-owned bridges in Northumberland County but may not work for all sidewalks.

Weighing in at approximately 585 pounds, the plow requires only a standard utility trailer and crew cab for transportation making this piece of equipment very mobile. There are no special certification requirements to operate the Zero Turn Plow, which gives any operator the ability to clean bridge sidewalks.

With a price tag of $9,200, not including a trailer, if needed, managers should perform a cost-benefit analysis to identify if the cost of the Zero Turn Plow is worth the overall benefit for their own needs.

Read More Maintenance Stories

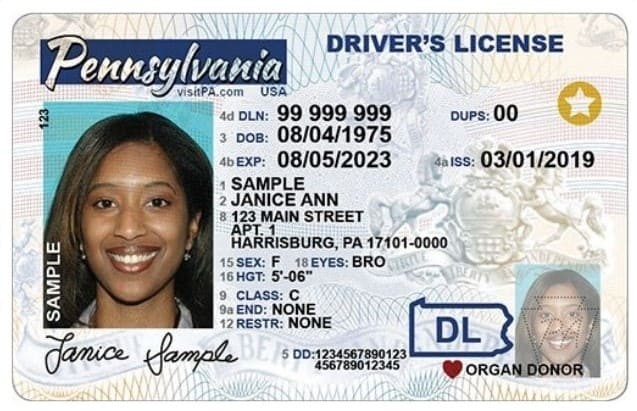

Among the bustling activity of the Children's Hospital of Philadelphia (CHOP) in November 2024, a temporary service popped up alongside the hospital's dedicated staff members - REAL ID processing stations.

For two days, PennDOT Driver and Vehicle Services (DVS) employees staffed a pop-up event at CHOP, turning it into a temporary extension of the medical center. Doctors, nurses, staff, and other workers took a break throughout the day to take care of an important task - applying for a REAL ID.

To help ensure Pennsylvanians are prepared for the upcoming federal REAL ID enforcement deadline of May 7, 2025, PennDOT is partnering with businesses, like CHOP, to offer pop-up events to help individuals get their REAL ID driver's licenses or photo identification (ID) cards by the deadline.

"This is exactly the type of customer-focused service Governor Shapiro has encouraged us to prioritize," said PennDOT's Deputy Secretary for Driver and Vehicle Services Kara Templeton. "This approach has the potential to eliminate barriers, improve customer service, and meet our residents where they are."

Getting a REAL ID is optional in Pennsylvania, but beginning May 7, 2025, Pennsylvanians will need a REAL ID-compliant driver's license or photo ID, or another form of federally acceptable ID, such as a valid passport or military ID, to board domestic commercial flights, enter a military base, or enter certain federal facilities that require a federally acceptable form of ID.

"These pop-up events are about bringing convenience to Pennsylvanians," Templeton said. "We're helping busy individuals get their REAL IDs without disrupting their schedules, and the feedback we've received has been overwhelmingly positive. People like the pop-up events and how conveniently they fit into their schedules during the workday."

By the end of the CHOP event, more than 300 people had their applications processed. Most of those individuals then received their REAL ID products in the mail within 15 business days.

This is the vision behind PennDOT's innovative REAL ID pop-up events, which are making life easier for Pennsylvanians by bringing the service directly to them. Instead of asking people to visit a driver license center, PennDOT is meeting customers where they already are - at their workplaces in their communities.